chinese manufacturer BS-1000 Scrap Cable Separator Machine for Copper Recycling

Machine BS-1000 waste cable wire granulator machine application and function: This big cable recycling plant is a large separation equipment which is specially used for processing the wire and cable, it has a high separation effect on the copper,iron,plastic. Machine the separation rate can reach 98%, the development of this equipment sucessfully solved the cost and the efficiency of the manuel disassemble and separation.Achieve the purpose of the purpose of comprehensive utilization,with high economic benefits and no dust no second pollution. The working principle: The equipment through the first crush the bulk material into 5~10cm, then convey into the shredder for second shred ,the final material is 10~15mm,after the screening of magnetic separator,iron and other magnetic substance are separated,copper and pvc are separated by vibrating separator, dust collect by the collector. The feeding capacity: 1000~1200KG/H(how much KG cables or wires put into the recycling line).

Technical parameter:

- Machine Parameters

- Diamension: 16000*8000*4200

- Capacitor:1000-1200KG/H

- Separation rate: 99%

- Buy chinese manufacturer BS-1000 Scrap Cable Separator Machine for Copper Recycling for sale,price,chinese manufacturer BS-1000 Scrap Cable Separator Machine for Copper Recycling exporter/importer,suppliers,factory,manufacturers in China.

-

SMS-5 Wholesale Scrap Automatic Used Copper Cable Stripper Wire Peeling Machine

SMS-5 Wholesale Scrap Automatic Used Copper Cable Stripper Wire Peeling Machine

-

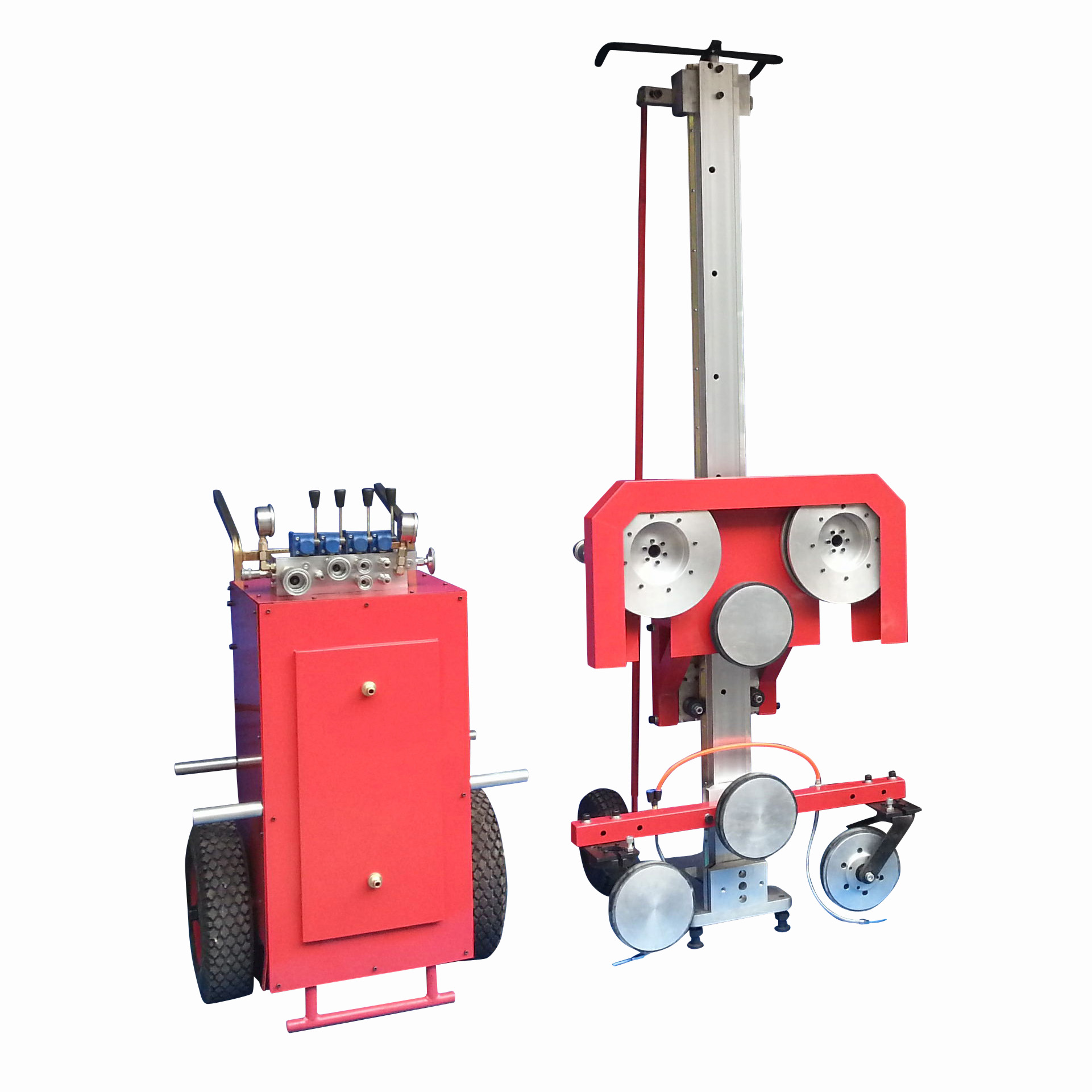

Dimond wire saw concrete cutting machine BS-90AM

Dimond wire saw concrete cutting machine BS-90AM

-

Multifunction Radiator Separating Machine From BSGH Equipment On Sale

Multifunction Radiator Separating Machine From BSGH Equipment On Sale

-

2021 High Quality BSGH Auto Car Motor Starter Rotor Cutting Recycler Machine For Copper Recycling On Sale

2021 High Quality BSGH Auto Car Motor Starter Rotor Cutting Recycler Machine For Copper Recycling On Sale

-

Electric power unit

Electric power unit

-

Small size small capacity metal wire cable granulator machine BS-D20 hot selling in India market

Small size small capacity metal wire cable granulator machine BS-D20 hot selling in India market

-

Hydraulic concrete crusher machine

Hydraulic concrete crusher machine

-

Lowest price highest quality metal cable wire granulation separator machine BS-D10 on sale

Lowest price highest quality metal cable wire granulation separator machine BS-D10 on sale

-

Heavy duty AC copper and aluminum radiator stripping separating recycling

Heavy duty AC copper and aluminum radiator stripping separating recycling

BS-40 Wet cable wire separator machine

BS-40 Wet cable wire separator machine

BS-20 Wet cable wire separator machine

BS-20 Wet cable wire separator machine

BS-10 Wet cable wire separator machine

BS-10 Wet cable wire separator machine

BS-05 Wet cable wire separator machine

BS-05 Wet cable wire separator machine

BS-800 manufacture gravity scrap copper pvc separation cable wire granulating recycling machine

BS-800 manufacture gravity scrap copper pvc separation cable wire granulating recycling machine

Wang Na

Wang Na